Talk to us

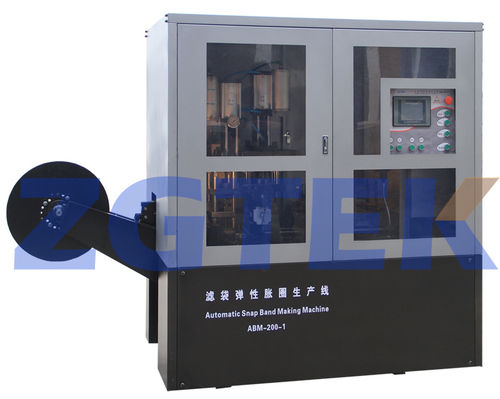

Automatic Snap Band Making MachBand Making Machine

MOQ : 1 , , Piece

Automatic Snap Band Making MachBand Making Machine Specification

- Power Source

- Electric

- Application

- Snap Band Manufacturing

- Frequency

- 50/60 Hz

- Welding

- Ultrasonic

- Phase

- Single Phase

- Power Consumption

- Approx 2.5 kW/h

- Automation Grade

- Automatic

- Current Range

- 5-12A

- Diameter

- Customizable

- Output Voltage

- 220V

- Equipment Type

- Band Making Machine

- Type

- Automatic Snap Band Making Machine

- Condition

- New

- Motor Type

- Servo Motor

- Material

- Stainless Steel

- Power

- 2.5 kW

- Voltage

- 220V

- Dimensions

- 1800 x 950 x 1650 mm

- Input Voltage

- 220V AC

- Rated Current

- 12 A

- Rated Capacity

- Up to 60 pieces/min

About Automatic Snap Band Making MachBand Making Machine

ZGTEK is recognized as the only company in the world expert in filter cage welding technologies and in China it is the only company capable of supplying high quality automatic ring making machines. ZGTEK has just started to develop wire mesh welding machines by cooperating with some mesh machine design experts.

Jiaxing Zhe Gong CNC Welding Machine Co., Ltd. (ZGTEK Co., Ltd) is located in Jiaxing City, Zhejiang Province (nearby Shanghai city), it's a partly state owned enterprise. The company possesses rich experience in resistance welding as well as automation, all based on its accumulated knowledge in wire welding.

Main Products

- Filter cage welding machine lines

- Ring making machines

- Round ring making machine (RM series)

- Oval ring making machine (OR series)

- Automatic ring making and welding machine (R series)

- Wire mesh welding machines

- Automatic wire mesh making machine (GWC series)

- CNC Reinforcement wire mesh welding machine.

Automatic Snap band making machine ABM-200-1

Automatic Snap Band Making Machines are used for making filter bags, (snap band riveting machine, or snap band welding machine). Offered machines are the fully automated solutions, employed for the manufacturing of snap bands.

Automatic snap band making machine for filter bags, or snap band riveting machine, this machine is the fully automatic solution for the production of snap bands.

Specification

- Model: ABM-200-1

- Snap band diameter: 100-200mm

- Snap band width: 19,20,25,30,35,40mm, other sizes can be customized

- Rivets spec: 3mm, half hollow

- Speed: 8s per piece

- Voltage: 220V 50/60Hz, or customized

- Power: 2.5KVA

- Compressed air consumption: 300L/min

- Air pressure: 0.6-0.8MPa

Features

- High speed

- High stability

- Easy operation with touch screen

Advanced Control System for Seamless Operation

Featuring a robust PLC touch screen, the Automatic Snap Band Making Machine enables intuitive operation and real-time monitoring, minimizing the need for manual intervention. The automated feeding and one-button start further streamline the manufacturing process, ensuring efficiency and productivity with minimal downtime.

Reliable and Safe Snap Band Production

Safety is paramount with an emergency stop button and low noise output, enhancing operator comfort and workplace safety. Automatic cutting and ultrasonic welding guarantee consistent product quality, making the machine suitable for high-volume, precise manufacturing environments.

Customization and Versatility in Manufacturing

This machine supports customizable band diameters and is adaptable for different production requirements. Designed for durability and flexibility, it accommodates a wide range of applications in the snap band industry, catering to the varied needs of manufacturers, exporters, and traders.

FAQs of Automatic Snap Band Making MachBand Making Machine:

Q: How does the Automatic Snap Band Making Machine operate?

A: The machine operates with a PLC touch screen control system, enabling easy operation through a one-button start. Automatic feeding, cutting, and ultrasonic welding processes are seamlessly integrated, providing consistent outputs with minimal manual input.Q: What materials and input requirements are necessary for this machine?

A: The machine is constructed from stainless steel for durability and requires a power supply of 220V AC with an air pressure of 0.5-0.8 MPa. It can process various snap band materials and accept customizable diameters as per production needs.Q: When should I consider customizing the band diameter or machine settings?

A: Customization is beneficial when you need specific snap band diameters for unique applications or wish to adjust settings for different materials and production capacities. The manufacturer can tailor these features according to your project requirements.Q: Where can this machine be installed, and what are the space requirements?

A: Due to its compact dimensions (1800 x 950 x 1650 mm), the machine can be installed in standard manufacturing facilities or workshops. Ensure the space allows for safe operator access and proper ventilation, meeting all electrical and safety requirements.Q: What is the typical process for manufacturing snap bands with this machine?

A: The process includes automatic feeding of material, precise automatic cutting, ultrasonic welding for secure closure, and continuous output, delivering up to 60 finished pieces per minute with consistent quality.Q: How does the machine enhance production efficiency and product quality?

A: Automation minimizes manual labor while ensuring high throughput (up to 3500 pieces/8 hours), consistent product quality through ultrasonic welding, and reduced operational noise, leading to a productive and comfortable work environment.Q: What are the key benefits of using this Automatic Snap Band Making Machine?

A: Major advantages include high production capacity, user-friendly automation, customized manufacturing options, robust safety features, low noise levels, and dependable construction from quality materials, making it invaluable for businesses specializing in snap band production.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry