Talk to us

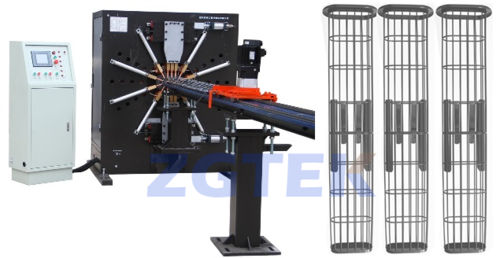

Oval Filter Bag Cage Making Machine Line

MOQ : 1 Piece

Oval Filter Bag Cage Making Machine Line Specification

- Output Voltage

- 24 V (for welding control)

- Equipment Type

- Filter Cage Making Machine Line

- Power Source

- Electric

- Diameter

- Customizable, standard up to 320 mm

- Phase

- Three Phase

- Application

- Manufacturing of oval filter bag cages for dust collectors

- Current Range

- 50-250 A

- Welding

- Auto MIG/Resistance Welding

- Automation Grade

- Automatic

- Frequency

- 50/60 Hz

- Power Consumption

- 7 kW

- Type

- Oval Filter Bag Cage Making Machine Line

- Condition

- New

- Motor Type

- AC Motor

- Material

- Stainless Steel / Mild Steel

- Power

- 5.5 kW

- Voltage

- 380 V

- Dimensions

- 9000 mm x 1500 mm x 2100 mm

- Input Voltage

- 380 V

- Rated Current

- 32 A

- Rated Capacity

- 30-40 cages/hour

- Noise Level

- 85 dB(A)

- Cage Length Range

- 1000mm 6000mm

- Finished Cage Feature

- Smooth welding spots and firm structure

- Material Feeding Method

- Automatic Wire Feeding

- Control System

- PLC Automatic Control

- Net Weight

- Approximately 2100 kg

- Operator Interface

- Touch Screen HMI

- Maintenance

- Easy access for regular maintenance

- Safety Features

- Emergency Stop, Protective Covers, Overload Protection

- Cutting Mode

- Hydraulic or Pneumatic Cutting

- Compressed Air Requirement

- 0.6 0.8 MPa

- Production Speed

- 8-10 cages per minute (depending on size and material)

- Cage Diameter Range

- Custom oval sizes (typically 120mm - 200mm short side)

- Wire Arrangement

- Parallel and precise alignment

About Oval Filter Bag Cage Making Machine Line

Oval Filter Bag Cage Making Machine Line

Specifications

- Model: DLN-16B

- Power frequency: 50/60Hz

- Wire Qty: 10/12/14/16/20

- Input voltage: 380V(2 phase) or customized

- Ring space: Can be of value, set in program

- Cage OD: Standard size 64mm*148mm, other sizes optional

- Cooling Method : natural cooling

Features :

- Provided with high welding speed, e.g. for a 16-wire oval cage, one ring yields only 0.24s.

- Rings are locked while the process of welding, insure optimal perpendicularity between ring plane & cage axis.

- Gear rack transmission come through high precision of ring space, the ring space can be fixed in the program via the user-friendly interface.

- The cage is pulled via servo motor, zero amassed locating tolerance.

- Has a pulling speed of 0.4m/s and the ring space precision is 0.1mm.

Top Collar Welder for Oval Cages

- This machine is used to fix the top collar to the oval cage

- When welding, D6S-80B uses the hanging surface as reference, which is exactly the way cages are mounted in the baghouses, also the top collar will be locked during welding, so it's much eaiser to achieve good perpendicularity

- Specifically designed cyclinder ensures stable air pressure and welding speed

- The newest version adopts touch screen controller, easy to operate

- Top support locating flange and adjustable stand ensures the perpendicularity between the support and cage axis

Advanced Automation for High Efficiency

Integrated PLC control and a user-friendly touch screen interface enable seamless operation with minimal manual intervention. Automated wire feeding ensures parallel and precise alignment, resulting in high production speedscapable of delivering up to 40 cages per hourwhile maintaining dimensional accuracy for each custom oval cage.

Customizable Cage Production

This machine line caters to diverse needs with adjustable cage length (1,0006,000 mm) and customizable oval diameters (normally 120200 mm short side, up to 320 mm standard). The flexibility makes it suitable for various dust filtration applications, adapting to both small and large manufacturing requirements.

Durability, Safety, and Low Maintenance

Manufactured from robust stainless or mild steel, the equipment is engineered for continuous industrial use. Its design features easy-access maintenance points, emergency stop functions, protective covers, and overload safeguards, ensuring operator safety and minimal downtime.

FAQs of Oval Filter Bag Cage Making Machine Line:

Q: How does the Oval Filter Bag Cage Making Machine Line ensure precise wire alignment?

A: The machine employs an advanced PLC system to automatically control wire feeding and alignment, guaranteeing parallel placement. Automated processes and precise mechanical guides ensure consistent cage geometry every time.Q: What are the typical applications for cages produced with this machine?

A: Cages manufactured with this equipment are primarily used in dust collector systems across industrial facilities. Their robust and precisely welded construction supports filter bags, enhancing air filtration efficiency and reliability.Q: When is regular maintenance required for optimal operation?

A: Routine maintenance is recommended at regular intervals based on usage intensity. The machine is designed for easy access to key components, allowing operators to perform cleaning, lubrication, and checks quickly for ongoing efficiency and longevity.Q: Where can the machine be installed, and what are the utility requirements?

A: The equipment can be installed in dedicated fabrication workshops or manufacturing plants with access to a three-phase 380V power supply and compressed air at 0.60.8 MPa. Sufficient floor space (about 9 x 1.5 meters) and proper ventilation are also essential.Q: What is the production speed and output range of the machine?

A: Depending on cage size and material, the machine can produce 810 oval cages per minute, translating to a rated capacity of 3040 cages per hour, ensuring high-volume demand is met efficiently.Q: How does the operator interact with and adjust the machine?

A: Operators use a touch screen human-machine interface (HMI) to input cage specifications, monitor production status, and make adjustments. Automated and intuitive controls minimize training and allow for rapid order changeovers.Q: What are the main benefits of using this automated machine line for cage making?

A: Key benefits include high-speed and consistent production, accurate customization of cage sizes, reduced labor, enhanced safety features, smooth and firm welding results, and simplified maintenanceultimately increasing productivity and product quality for filter cage manufacturers.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Oval Filter Bag Cage Making Machine Line Category

Oval Filter Bag Cage Making Machine Line DLN-16B

Price Range 20000.00 - 40000.00 USD ($)

Minimum Order Quantity : 1 Piece

Type : Oval Filter Bag Cage Making Machine Line

Welding : Other, Resistance Welding

Power Source : Electric

Voltage : 380 V

Oval Filter Bag Cage Making Machine Line WG

Price Range 1500.00 - 2500.00 USD ($)

Minimum Order Quantity : 1 Piece

Type : Oval Filter Bag Cage

Welding : Other, Spot Welding

Power Source : Electric

Voltage : 220 V

Oval Filter Bag Cage Making Machine Line D6S-80B

Price Range 12000.00 - 20000.00 USD ($)

Minimum Order Quantity : 1 Piece

Type : D6S80B

Welding : Automated Welding System, Other

Power Source : Electric

Voltage : 220 V

Oval Filter Bag Cage making Machine line DLJ-80B

Price Range 15000.00 - 20000.00 USD ($)

Minimum Order Quantity : 1 Piece

Type : Industrial Manufacturing Equipment

Welding : Other, Spot welding automation

Power Source : Electric

Voltage : 380 V

Send Inquiry

Send Inquiry