Talk to us

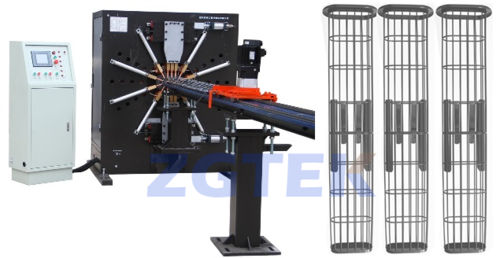

Oval Filter Bag Cage Making Machine Line DLN-16B

MOQ : 1 Piece

Oval Filter Bag Cage Making Machine Line DLN-16B Specification

- Welding

- Resistance Welding

- Current Range

- 5560 A

- Power Source

- Electric

- Phase

- Three Phase

- Power Consumption

- 32 kW

- Frequency

- 50 Hz

- Diameter

- Customer specified

- Equipment Type

- Oval Filter Bag Cage Making Machine Line

- Output Voltage

- 15 V

- Application

- Filter Bag Cage Production

- Automation Grade

- Automatic

- Type

- Oval Filter Bag Cage Making Machine Line

- Condition

- New

- Motor Type

- Servo Motor

- Material

- Mild Steel

- Power

- 32 kW

- Voltage

- 380 V

- Dimensions

- 9500 1800 2100 mm

- Input Voltage

- 380 V / 50 Hz

- Rated Current

- 60 A

- Rated Capacity

- 16 cages/min

About Oval Filter Bag Cage Making Machine Line DLN-16B

Oval Filter Bag Cage Making Machine Line DLN-16B

- Oval Filter Bag Cage Making Machine

- Model: DLN-16B

- Wire Qty: 10/12/14/16/20

- Ring space: can be any value, set in program

- Cage OD: standard size 64mm*148mm, other sizes optional

- Input voltage: 380V(2 phase) or customized

- Power frequency: 50/60Hz

- Cooling method: natural cooling

Features

- Very high welding speed, e.g. For a 16-wire oval cage, one ring takes only 0.24s

- Rings are locked while welding, ensures good perpendicularity between ring plane and cage axis

- Gear rack transmission achieves high precision of ring space, ring space can be set in the program through the user-friendly interface

- The cage is pulled by servo motor, no accumulated locating tolerance, ring space precision is 0.1mm, pulling speed is 0.4m/s

- Function of bad weld detection and auto re-welding

- Material selection, different welding parameters for mild steel, galvanized steel and stainless steel

Industrial-Grade Performance

Designed for robust and continuous operation, the DLN-16B delivers a consistent output of oval, flat-oval, and custom-shaped filter bag cages. Its automatic control system optimizes production speed, while precision rollers ensure uniform wire forming for a superior end product.

Efficient and Flexible Operations

The machine line is adaptable to various production needs, with an adjustable forming speed and compatibility with multiple cage shapes and wire diameters. Its PLC control system allows for streamlined adjustments and consistent results, reducing manual intervention and operator requirements.

Reliable Construction and Low Maintenance

Manufactured from high-quality mild steel and fitted with a servo motor for efficient operation, the DLN-16B is designed for longevity. The resistance welding process and sturdy build ensure minimal downtime and high durability, making it a dependable choice for filter bag cage production.

FAQs of Oval Filter Bag Cage Making Machine Line DLN-16B:

Q: How does the DLN-16B ensure fast and consistent cage production?

A: The machine uses precision rollers and a PLC control system, enabling adjustable forming speeds and multi-spot resistance welding. This setup ensures that each cage is formed uniformly with minimal defects, achieving a production rate of 120180 pieces per hour.Q: What types of filter bag cages can be manufactured with this machine line?

A: The DLN-16B supports a range of cage types, including oval, flat-oval, and custom-shaped designs, accommodating up to 24 wires per cage to meet versatile filtration requirements.Q: When should routine maintenance be performed on the DLN-16B machine line?

A: Routine maintenance should be scheduled according to usage frequency and manufacturer recommendations, typically involving regular checks on the rollers, welding system, and PLC control components to maintain optimal performance and prevent unexpected downtime.Q: Where is the DLN-16B filter bag cage making machine commonly installed?

A: This machine line is ideal for industrial filtration component manufacturing facilities, such as those engaged in mass producing filter bag cages for air and dust collection systems.Q: What is the process of producing a filter bag cage with the DLN-16B?

A: The process begins with feeding wires into the machine, which are formed into the desired oval or custom shape by precision rollers. The wires are then welded at multiple spots, ensuring strong joins, before the finished cage is cut and ejected automatically.Q: How many operators are needed to run the DLN-16B machine line efficiently?

A: The machine is designed for automation and requires only 12 operators for efficient monitoring and handling, streamlining labor requirements while maintaining high output.Q: What are the main benefits of using this oval filter bag cage making machine line?

A: Key benefits include high production speed, consistent quality, reduced manual intervention, versatility in cage shapes and wire diameters, and long-term durability, all contributing to improved operational efficiency and product reliability.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Oval Filter Bag Cage Making Machine Line Category

Oval Filter Bag Cage Making Machine Line

Price Range 10000.00 - 15000.00 USD ($)

Minimum Order Quantity : 1 Piece

Input Voltage : 380 V

Voltage : 380 V

Application : Manufacturing of oval filter bag cages for dust collectors

Automation Grade : Automatic

Oval Filter Bag Cage Making Machine Line WG

Price Range 1500.00 - 2500.00 USD ($)

Minimum Order Quantity : 1 Piece

Input Voltage : 220 V

Voltage : 220 V

Application : Filter Bag Frame Manufacturing

Automation Grade : SemiAutomatic

Oval Filter Bag Cage Making Machine Line D6S-80B

Price Range 12000.00 - 20000.00 USD ($)

Minimum Order Quantity : 1 Piece

Input Voltage : 220 V

Voltage : 220 V

Application : Oval Filter Bag Cage Manufacturing

Automation Grade : SemiAutomatic

Oval Filter Bag Cage making Machine line DLJ-80B

Price Range 15000.00 - 20000.00 USD ($)

Minimum Order Quantity : 1 Piece

Input Voltage : 380 V

Voltage : 380 V

Application : Manufacturing filter bag cages

Automation Grade : Automatic

Send Inquiry

Send Inquiry