Talk to us

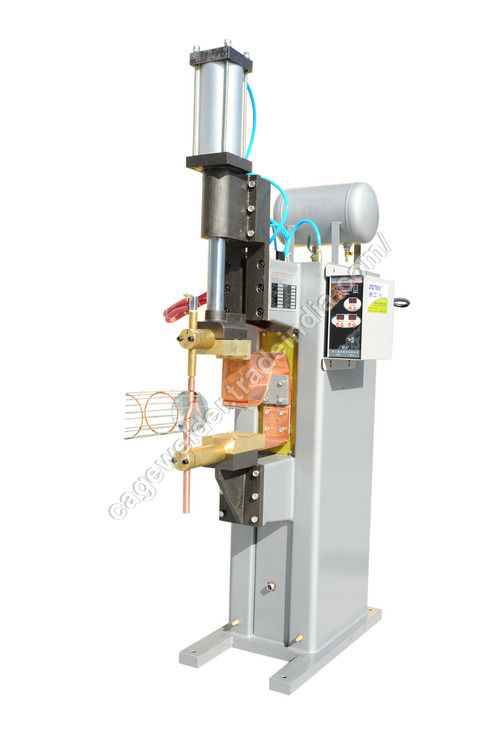

Ring Butt Welder

MOQ : 1 , , Piece

Ring Butt Welder Specification

- Output Voltage

- Up to 20V

- Power Source

- Electric

- Equipment Type

- Butt Welding Machine

- Power Consumption

- Low

- Application

- Industrial, Ring joint welding

- Automation Grade

- Automatic

- Welding

- Butt Welding

- Phase

- Single & Three Phase

- Current Range

- Up to 800A

- Frequency

- 50 Hz

- Diameter

- Up to 100 mm rings

- Type

- Ring Butt Welder

- Condition

- New

- Motor Type

- AC Motor

- Material

- Mild Steel

- Power

- 7.5 kVA

- Voltage

- 220V / 380V

- Dimensions

- Approx. 1100 x 750 x 1350 mm

- Input Voltage

- 220V / 380V

- Rated Current

- Up to 800A

- Rated Capacity

- Up to 10 mm ring

About Ring Butt Welder

Ring Butt WelderWe have a strong stand in the market as the manufacturer, supplier and exporter of Ring Butt Welder. These products are used in various industries for manufacturing wire rings. Checked to ensure their supreme and flawless quality, these products provide accurate and optimum performance. These products are packed in special packaging material so as to ensure their safe and secure transit. Ring Butt Welder are known in the global market for its longer service life, low maintenance, resistance against corrosion and high strength.

Specifications:

-

Model: UR-40

-

Input Voltage: 380V (2-phase)

-

Power Frequency: 50Hz

-

Control Unit: KD-U08B

-

Cooling Method: Natural cooling

-

Air Pressure: 0.6-0.8 MPa

-

Insulation Grade: F

-

Power Capacity: 40 KVA

-

Working Load: 15 KVA

-

Air Flow: 200 L/min

Features

-

High speed, capable of welding 8000 rings per 8-hour shift.

-

Small heat affected area, approximately 3-4mm, especially applicable for welding galvanized wire.

-

This machine is not recommended to be used to weld stainless steel rings, there is an argon arc welding(tig welding) machine available specificly for welding stainless steel ring, the operating method is the same.

Filter Cages - round, star, oval, flat, peanut, spider and other odd shapes, with different connections, all can be customized.

Round cage size: OD100-200mm

Material: Mild steel wire, Stainless steel wire, Galvanized carbon steel wire, Titanium steel wire, etc.

Sizes of steel wire: 2.8-6mm

Precision and Efficiency in Ring Welding

The Ring Butt Welder combines precision engineering with user-friendly automation to deliver exceptional results for industrial ring joint welding tasks. Its robust build and integrated mild steel construction ensure durability and consistent quality, even under heavy-duty usage. The fully automatic system minimizes operator intervention, boosting productivity while ensuring uniform welds every time.

Versatile Power Options and Compatibility

Designed to operate on both 220V and 380V, this welder accommodates varying industrial setups. Supporting both single and three-phase power, it provides flexibility for different electrical environments without the need for additional converters. Large rings up to 100 mm in diameter and thick rings up to 10 mm are welded with ease, meeting a broad spectrum of application requirements.

FAQs of Ring Butt Welder:

Q: How does the Ring Butt Welder operate in an industrial environment?

A: The Ring Butt Welder utilizes an automatic control system driven by a 7.5 kVA AC motor. When connected to a suitable power source, the machine precisely aligns and welds mild steel ring joints, delivering efficient and repeatable results suitable for large-scale industrial production.Q: What materials and ring sizes can this welding machine process?

A: This machine is designed to weld mild steel rings with diameters up to 100 mm and thicknesses up to 10 mm. Its robust construction and high current capacity make it suitable for various ring sizes and industrial-grade steel.Q: When is the right time to use a Ring Butt Welder?

A: The Ring Butt Welder is ideal whenever strong, precise joints are required in ring manufacturing or assembly processes. It is especially beneficial for high-volume production lines and applications where consistent weld quality is critical.Q: Where can this welder be installed and used effectively?

A: This equipment is suitable for installation in factories, workshops, and industrial facilities where ring fabrication or assembly occurs. Its moderate dimensions ensure it fits most industrial settings without taking up excessive space.Q: What is the process for operating the Ring Butt Welder?

A: Operators place prepared steel rings into the welding station, set the appropriate voltage and current, and initiate the automated welding sequence. The machine handles alignment, heating, and joining, minimizing manual intervention and operator training requirements.Q: How does using this welding machine benefit manufacturers and suppliers?

A: Manufacturers and suppliers benefit from increased throughput, consistent weld quality, and reduced labor costs. Its automated operation and low power consumption optimize production efficiency and lower overall operating expenses.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Filter Cages & Cage Parts Category

Top Collar Welder for Filter Cage

Price Range 3000.00 - 4000.00 USD ($)

Minimum Order Quantity : 1 , , Piece

Dimensions : 2200 mm x 950 mm x 1900 mm

Material : Mild Steel / Stainless Steel

Condition : New

Type : Top Collar Welder

Wire Straightening Machine

Price Range 1500.00 - 2500.00 USD ($)

Minimum Order Quantity : 1 , , Piece

Dimensions : 1200 mm x 600 mm x 900 mm

Material : Mild Steel

Condition : New

Type : Wire Straightening Machine

Automatic Wire Decoiler Machine

Price Range 1000.00 - 3000.00 USD ($)

Minimum Order Quantity : 1 , , Piece

Dimensions : 1200 x 900 x 1200 mm

Material : Mild Steel

Condition : New

Type : Automatic Wire Decoiler Machine

Bottom Cap Welder For Filter Cage

Price Range 3000.00 - 4000.00 USD ($)

Minimum Order Quantity : 1 , , Piece

Dimensions : 1200 mm x 700 mm x 1450 mm

Material : Mild Steel (MS)

Condition : New

Type : Bottom Cap Welder

Send Inquiry

Send Inquiry