Talk to us

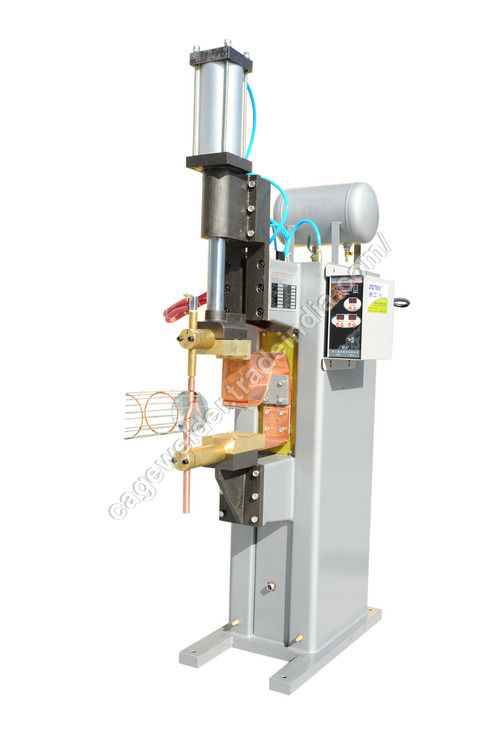

Top Collar 6-Point Welder for Oval Cage

MOQ : 1 Piece

Top Collar 6-Point Welder for Oval Cage Specification

- Current Range

- 40 70 A

- Power Source

- Electric

- Equipment Type

- Specialized Welding Machine for Filter Cages

- Phase

- Three Phase

- Power Consumption

- Low

- Welding

- Spot Welding

- Diameter

- Customizable as per cage size

- Output Voltage

- 24 V

- Frequency

- 50 Hz

- Application

- Welding top collars for oval cages in filtration and dust collector industries

- Condition

- New

- Motor Type

- Heavy Duty Electric

- Material

- Mild Steel, Stainless Steel

- Power

- 3.5 kW

- Voltage

- 415 V

- Dimensions

- 1900 x 950 x 1800 mm

- Input Voltage

- 415 V AC

- Rated Current

- 70 A

About Top Collar 6-Point Welder for Oval Cage

Backed by the team of skilled and trained professionals, we are able to manufacture, supply and export Wire Bending Machine. These products are used for bending various ferrous and non-ferrous metals. High quality raw materials and components have been procured from the trusted sources of the market for the manufacturing of these products. Our team of qualified and trained quality controllers is involved in testing of these products to ensure their supreme quality. Wire Bending Machine is packed in special packaging material so as to ensure its safe and secure transit.

Specifications:

-

Model: D6S-80B

-

Input Voltage: 380V (2-phase) or specified by customer

-

Power Freq.: 50/60Hz

-

Power Capacity: 80KVA

-

Instant Power in Sync Mode: 20KVA

-

Air Flow: 300L/min

-

Air Pressure: 0.6-0.8MPa

-

Cooling Method: Natural cooling

-

Insulation Grade: F

-

Weight: 600KG

Features

-

Specifically designed cylinder ensures stable air pressure and welding speed.

-

One-piece machine body secures its rigidity.

-

Adopting KD-08B controller and reliable welding loop.

-

Top support locating flange and adjustable stand ensures the perpendicularity between the support and cage axis.

-

Top cap welder is also applicable for welding connecting rings for multi-section cages.

Advanced Welding for Filter Cages

The Top Collar 6-Point Welder is crafted to streamline the welding of top collars onto oval filter cages, essential in filtration and dust collection systems. With its solid mild and stainless steel build and advanced spot welding technology, this machine ensures strong and precise welds. Thanks to its low power consumption and electric operation, it caters to large-scale manufacturers and suppliers requiring continuous and consistent production output.

Customizable and High-Efficiency Design

Built to accommodate various cage dimensions, the welders diameter can be tailored to specific filter cage sizes. The easy-to-operate controls and stable three-phase power supply deliver uniform welds and reliable performance. Whether for exporters, traders, or manufacturers, this equipment promises robust operation, minimal maintenance, and adaptability in diverse industrial settings.

FAQs of Top Collar 6-Point Welder for Oval Cage:

Q: How does the Top Collar 6-Point Welder work for oval cage applications?

A: The welder uses spot welding technology to securely attach top collars to oval filter cages. Customizable dimensions ensure it fits a variety of cage sizes, providing efficient and consistent welds crucial for filtration and dust collector assemblies.Q: What are the main benefits of using this specialized welding machine?

A: This machine offers robust construction, reliable electric operation, and low power consumption. Its customizable design and strong weld quality improve productivity, reduce manual labor, and enhance the durability of filter cage assemblies.Q: When is it best to use the Top Collar 6-Point Welder?

A: It is ideal for integration into manufacturing lines where consistent, high-quality welding of top collars on oval cages is required, especially in the production of filtration or dust collection equipment.Q: Where can this welder be used?

A: This machine is suitable for use in industrial manufacturing settings such as filter cage production facilities, dust collector manufacturing plants, or export/import businesses dealing in industrial filtration equipment.Q: What is the process of welding with this machine?

A: The process involves placing the oval filter cage within the designated area, setting the desired diameter, and activating the spot welding operation. The heavy-duty electric motor and precise controls ensure each collar is securely attached.Q: How is power consumption managed during operation?

A: The welder operates with a 3.5 kW power rating and is engineered for low power consumption. Its three-phase design and efficient motor reduce energy demand while maintaining optimal welding performance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Filter Cages & Cage Parts Category

Top Collar Positioning Welder

Price Range 13000.00 - 16000.00 USD ($)

Minimum Order Quantity : 1 , , Piece

Welding : Other, Spot Welding

Dimensions : 1300 x 700 x 1600 mm

Condition : New

Application : Collar Attaching in Garment Manufacturing

Bottom Cap Crimper

Price Range 1000.00 - 2000.00 USD ($)

Minimum Order Quantity : 1 , , Piece

Welding : Other, No

Dimensions : 450 mm x 350 mm x 700 mm

Condition : New

Application : Crimping bottle bottom caps in pharmaceuticals, cosmetic, and chemical industries

Bottom Cap Welder For Filter Cage

Price Range 3000.00 - 4000.00 USD ($)

Minimum Order Quantity : 1 , , Piece

Welding : Other, Spot/Projection Welding

Dimensions : 1200 mm x 700 mm x 1450 mm

Condition : New

Application : Filter Cage Bottom Cap Welding

Split Cage 2 Joint Ring Connection

Price Range 1.00 - 2.00 USD ($)

Minimum Order Quantity : 100 Pieces

Welding : Other, Seam welded ensuring durability

Dimensions : Various sizes available

Condition : New

Application : Dust collection systems

Send Inquiry

Send Inquiry