Talk to us

Filter Cages

MOQ : 100 Pieces

Filter Cages Specification

- Welding

- Spot Welded / Seam Welded

- Application

- Dust Collection Systems, Bag Filter Units

- Equipment Type

- Filter Cage

- Type

- Filter Cages

- Condition

- New

- Material

- Mild Steel / Stainless Steel

- Dimensions

- Customized as per requirement

About Filter Cages

| |

Filter Cages

Our huge range of products comprise Filter Cages that are very popular in the market. Made of high quality raw materials and components that are supposed to be the best in the market, these products provide accurate and optimum performance. These products find application in different industries for collecting duct and other particles in order to purify air. High durability, smooth operation, effective functioning and less maintenance are some of the main features of these products. Filter Cages are packed in special packaging material so as to ensure their safe and secure transit.

Other details:

Types of cage: Round cage, Oval (flat) cage, Star cage, Split cage, Spider cage, etc.

-

Cage size: dia.100-200mm

-

Steel wire of Cage: Mild steel wire, Stainless steel wire, Galvanized carbon steel wire, etc.

-

Steel wire thickness: 2.5-5mm

Requirements of one cage welding line

-

Workshop: 10m*20m

-

Power capacity: 45-50KVA

-

Workers: 5 people for a running line.

Output

-

For example: Filter cage: 24 vertical wires * 6000mm Length, Ring distance: 50-200mm.

-

Daily output: 250pcs (10hours/day)

- Annual output: 70000pcs (280days).

Filter Cages - round, star, oval, flat, peanut, spider and other odd shapes, with different connections, all can be customized.

Round cage size: OD100-200mm

Material: Mild steel wire, Stainless steel wire, Galvanized carbon steel wire, Titanium steel wire, etc.

Sizes of steel wire: 2.8-6mm

Customizable Precision Engineering

Every filter cage is tailored to meet your specific requirements for size, shape, and materialbe it mild steel or stainless steel. Our attention to detail guarantees a perfect fit and optimal function within existing dust collection or bag filter systems. We utilize both spot-welded and seam-welded processes to ensure structural integrity, resulting in long-lasting and reliable products.

Broad Industry Applications

Our filter cages play a vital role in various industries by supporting dust collection systems and bag filter units. Whether for manufacturing, processing, or other industrial environments, these cages effectively contribute to clean air management, improving workplace safety and equipment life.

FAQs of Filter Cages:

Q: How are these filter cages manufactured for strength and reliability?

A: We use either spot welding or seam welding on mild steel or stainless steel to fabricate our filter cages. This robust construction process enhances the cages rigidity and ensures they can withstand the operating demands of dust collection systems.Q: What are the typical applications for your filter cages?

A: Our filter cages are primarily used in dust collection systems and bag filter units, serving industries where air quality control and contaminant removal are essential for safe and efficient operations.Q: When should filter cages be replaced in a dust collection system?

A: It is advisable to inspect and potentially replace filter cages whenever there are signs of corrosion, bent wires, or compromised structure to ensure sustained filtration efficiency and protect the integrity of the filter bags.Q: Where are your filter cages commonly utilized?

A: These filter cages are commonly installed in industrial facilities across sectors such as cement, power generation, pharmaceuticals, and food processing, where effective particulate filtration is necessary.Q: What is the process for customizing filter cage dimensions?

A: You can specify your required dimensions and materials when placing an order. Our technical team will collaborate with you to design and manufacture cages that precisely accommodate your bag filter housings and system requirements.Q: How do filter cages benefit dust collection performance?

A: Filter cages support the filter bags, preventing collapse during operation and maximizing their surface area for effective dust capture. This extends bag life and boosts the overall efficiency of the dust collection unit.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Filter Cages & Cage Parts Category

Ring Butt Welder

Price Range 2500.00 - 3500.00 USD ($)

Minimum Order Quantity : 1 , , Piece

Application : Industrial, Ring joint welding

Material : Mild Steel

Condition : New

Dimensions : Approx. 1100 x 750 x 1350 mm

Top Collar 6-Point Welder for Oval Cage

Price Range 10000.00 - 20000.00 USD ($)

Minimum Order Quantity : 1 Piece

Application : Welding top collars for oval cages in filtration and dust collector industries

Material : Mild Steel, Stainless Steel

Condition : New

Dimensions : 1900 x 950 x 1800 mm

Wire Bending Machine

Price Range 1500.00 - 2500.00 USD ($)

Minimum Order Quantity : 1 , , Piece

Application : Wire Bending for Industrial and Manufacturing

Material : Mild Steel

Condition : New

Dimensions : 1100 mm x 700 mm x 1300 mm

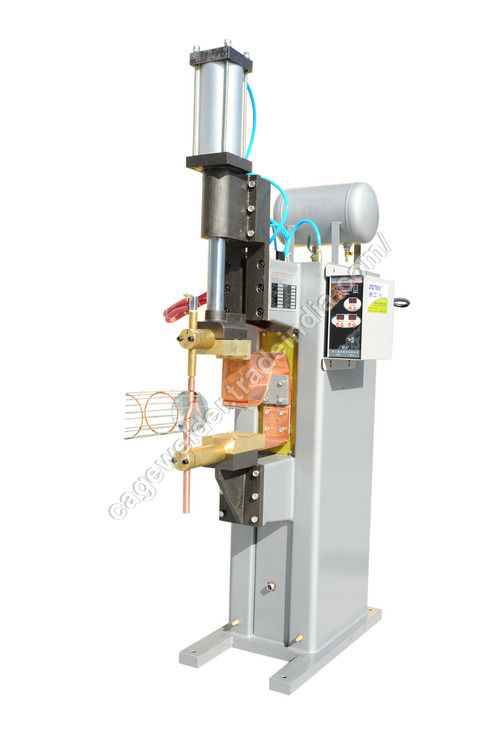

Bottom Cap Welder For Filter Cage

Price Range 3000.00 - 4000.00 USD ($)

Minimum Order Quantity : 1 , , Piece

Application : Filter Cage Bottom Cap Welding

Material : Mild Steel (MS)

Condition : New

Dimensions : 1200 mm x 700 mm x 1450 mm

Send Inquiry

Send Inquiry