Talk to us

Round Filter Cage Welding Machine line WB-160

MOQ : 1 Piece

Round Filter Cage Welding Machine line WB-160 Specification

- Product Type

- Round Filter Cage Welding Machine line WB-160

- General Use

- For manufacturing and welding round filter cages used in filtration systems

- Material

- Stainless Steel

- Type

- Automatic Welding Line

- Capacity

- Up to 160 cages per hour

- Weight (kg)

- Approx. 2100 kg

- Computerized

- Yes

- Automatic

- Yes

- Ozone Generator

- No

- UV Sterilizer

- No

- Control System

- PLC Control

- Filter Bag No.

- Customizable as per requirement

- Filter Area

- Configurable based on cage size

- Voltage

- 380V, 50Hz

- Motor

- High-efficiency AC motor

- Dimension (L*W*H)

- 5800 mm 1500 mm 2100 mm

- Feature

- High production speed, precise welding, customizable cage dimensions

- Color

- Industrial Grey

About Round Filter Cage Welding Machine line WB-160

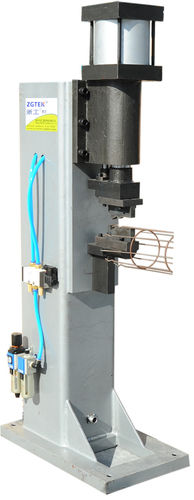

Round Filter Cage Welding Machine line WB-160

- Wire Bending Machine for Split Cages

- Model: WB-160

- Input voltage: 220V(1-phase) or specified by customer

- Air pressure: 0.6-0.8MPa

- Air flow: 150L/min

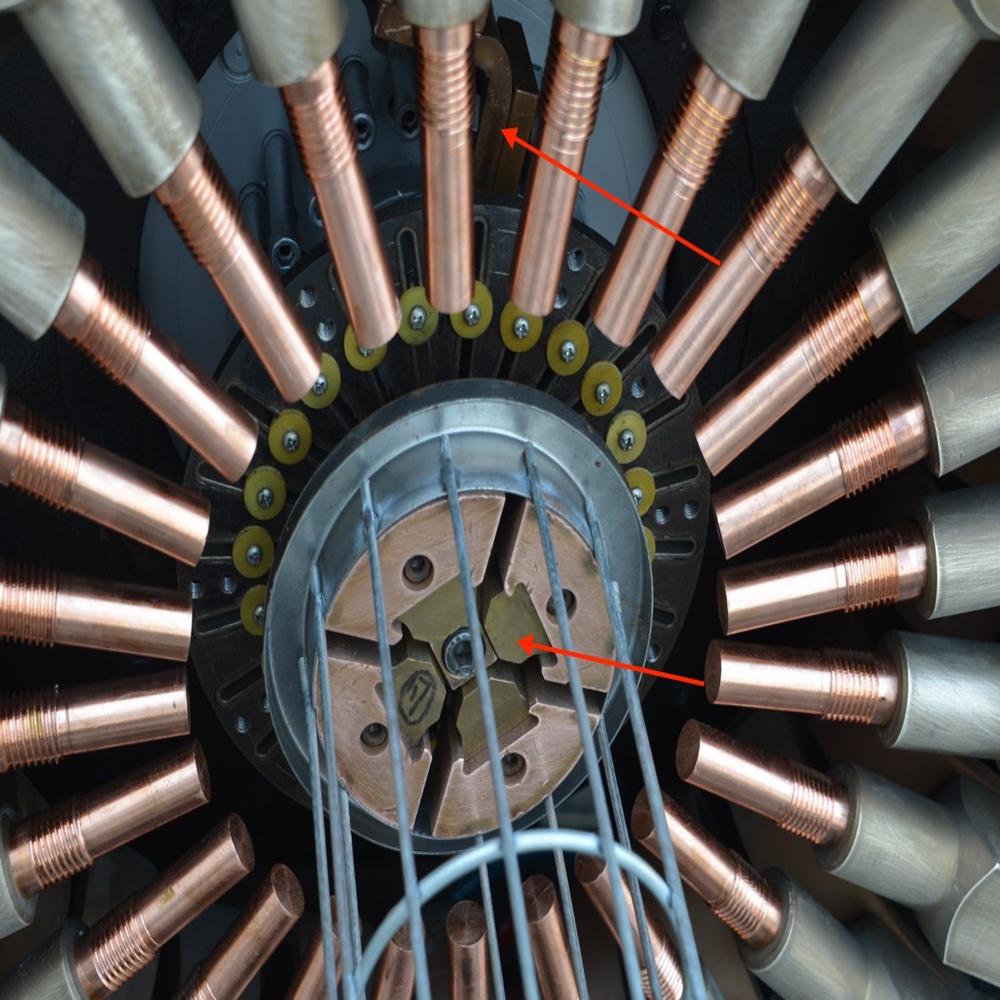

Advanced Automatic Welding Technology

The WB-160 is engineered with multi-point spot welding and seam welding mechanisms, powered by a high-efficiency AC motor and integrated inverter welder. Its PLC control system and touchscreen HMI interface facilitate precise adjustments and monitoring throughout the entire manufacturing process.

Versatile and Customizable Production

Capable of handling wire diameters from 2 mm to 6 mm and producing filter cages in a variety of diameters and lengths, the WB-160 allows manufacturers to easily adapt to different filter bag specifications. The line includes straightening, cutting, and welding sections for a seamless production workflow.

Safety and Maintenance Simplified

Equipped with emergency stops, overload protection, and safety light curtains, the WB-160 prioritizes operator safety. Its easy-access design and integrated water cooling system reduce downtime for cleaning and part replacement, ensuring reliable, long-term operation.

FAQs of Round Filter Cage Welding Machine line WB-160:

Q: How does the WB-160 Round Filter Cage Welding Machine operate?

A: The WB-160 operates with a PLC-controlled automatic system, featuring multi-point spot welding, seam welding, and integrated sections for wire straightening, cutting, and welding. Operators interact with an intuitive touchscreen HMI to configure and monitor the process.Q: What are the benefits of using this welding machine in filter cage manufacturing?

A: The WB-160 offers precise, high-speed production (up to 160 cages per hour), consistent weld quality, and the flexibility to handle various cage sizes. Its automatic functions and integrated safety features enhance productivity while reducing labor requirements and error rates.Q: When should the machine be maintained, and how easy is the maintenance process?

A: Routine maintenance can be performed easily, thanks to the machines accessible design, allowing for swift cleaning and part replacement. Preventive maintenance schedules help ensure uninterrupted performance and prolong the equipments service life.Q: Where can this machine be installed, and what are the installation requirements?

A: The WB-160 should be installed on a level, solid foundation with access to a 380V, 50Hz power supply, and an air pressure source of 0.60.8 MPa. Proper site preparation ensures operational stability and safety.Q: What materials and cage sizes are supported by the WB-160?

A: This machine is optimized for stainless steel wires ranging from 2 mm to 6 mm in diameter, supporting cage diameters between 100 mm and 300 mm, and lengths up to 2500 mm. Cage configurations are customizable as per filtration system requirements.Q: How does the integrated cooling system enhance the welding process?

A: The machines built-in water cooling system maintains optimal temperatures during operation, which preserves welding quality, extends component life, and supports continuous high-speed production without overheating issues.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Round Filter Cage Welding Machine Line Category

Round Filter Cage Welding Machine line DLN-24-6

Price Range 30000.00 - 50000.00 USD ($)

Minimum Order Quantity : 1 Piece

Feature : Other, High welding precision, continuous operation, energy efficient

Material : Other, Mild Steel (MS)

Product Type : Round Filter Cage Welding Machine Line

Round Filter Cage Welding Machine line DX-80

Price Range 3000.00 - 4000.00 USD ($)

Minimum Order Quantity : 1 Piece

Feature : Other, Automatic straightening, forming, welding, and ejecting

Material : Other, Mild steel/Carbon steel

Product Type : Round Filter Cage Welding Machine Line

Top collar 4-point positioning welding machine for filter bag cage D4S-80-2

Price Range 10000.00 - 20000.00 USD ($)

Minimum Order Quantity : 1 , , Piece

Send Inquiry

Send Inquiry