Talk to us

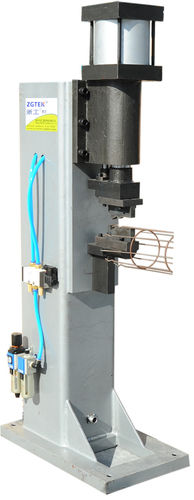

Round Filter Cage Welding Machine line DLN-24-6

MOQ : 1 Piece

Round Filter Cage Welding Machine line DLN-24-6 Specification

- Product Type

- Round Filter Cage Welding Machine Line

- General Use

- Filter cage welding for dust collector filters

- Material

- Mild Steel (MS)

- Type

- Automatic Welding Line

- Capacity

- Up to 24 filter cages simultaneously

- Weight (kg)

- Approximately 3000 kg

- Computerized

- Yes

- Automatic

- Yes

- Ozone Generator

- No

- UV Sterilizer

- No

- Control System

- PLC (Programmable Logic Controller) based

- Filter Bag No.

- 24

- Filter Area

- Customizable depending on filter design

- Voltage

- 380 V / 415 V, 3 Phase, 50 Hz

- Motor

- Siemens or equivalent, 7.5 kW

- Dimension (L*W*H)

- Approx. 8000 mm x 2000 mm x 2500 mm

- Feature

- High welding precision, continuous operation, energy efficient

- Color

- Industrial Grey

About Round Filter Cage Welding Machine line DLN-24-6

Round Filter Cage Welding Machine line DLN-24-6

- Filter cage body welding machine the 6th generation

- Model: DLN-24-6

- Cage wire quantity: 8/10/12/14/16/18/20/22/24

- Ring space: can be set at any value

- Cage outer diameter: 100-200mm

- Rail length: standard 7m, up to 10m can be customized

Features

- One machine can weld the whole cage, including top collar, cage body and bottom cap

- Very high welding speed, e.g. for a 12-wire cage, one ring takes only 0.18s

- Automatic cage pulling, ring space can be set in the program through the user-friendly interface.

- The cage pulling carriage is equipped with bearings, runs on the rail with linear guides, it's smooth and precise

- Function of bad weld detection and auto re-welding

High Efficiency, Automated Cage Welding

The DLN-24-6 eliminates labor-intensive filter cage fabrication by automating the entire welding process. With PLC control and a touch screen HMI, operators enjoy ease of use while maintaining production speeds up to 50 cages per hour. Its robust construction and simultaneous multi-cage capability (up to 24 at once) significantly boost productivity and throughput for dust collector filter manufacturers.

Reliable Operation and Integrated Safety

Built with safety as a priority, the machine is equipped with overload protection, emergency stop buttons, and interlock guards. Operators benefit from minimal downtime due to the integrated water cooling system, ensuring consistent operation even during extended shifts. The equipment is manufactured from high-quality mild steel and supports full onsite installation, commissioning, and technical service.

FAQs of Round Filter Cage Welding Machine line DLN-24-6:

Q: How does the DLN-24-6 Round Filter Cage Welding Machine operate?

A: The DLN-24-6 uses resistance/spot welding technology controlled via a PLC-based system and touch screen HMI. Operators load wires and configure the desired cage dimensions; the machine then welds up to 24 cages at once, ensuring high precision and uniformity. An integrated water cooling system maintains optimal operating temperature during continuous operation.Q: What types of filter cages are suitable for this machine?

A: This welding line is tailored for manufacturing filter cages used in pulse jet dust collectors and baghouse systems. It supports wire diameters from 3 mm to 6 mm and cage diameters between 100 mm and 200 mm, with customizable filter areas depending on your specific dust collector design.Q: When should maintenance be performed on this welding machine?

A: Routine maintenance should be conducted as per the manufacturers guidelines, ideally after every production cycle or as indicated by the machines diagnostics. Regular checks on the cooling system, welding electrodes, and safety interlocks help ensure stable, long-term performance.Q: Where can the DLN-24-6 be installed and used?

A: The machine is suitable for installation in industrial production lines, particularly in facilities manufacturing filter cages for dust collection systems. As an automatic, computerized system, it requires a 380 V / 415 V, 3-phase, 50 Hz power supply, and an air requirement of 0.6 MPa. Onsite installation and commissioning support is available.Q: What are the main benefits of using the DLN-24-6 welding machine?

A: Key benefits include high welding accuracy, increased production capacity, energy efficiency, and reduced labor costs. Its robust safety features and automation make it reliable, while the ability to weld multiple cages simultaneously accelerates manufacturing and order fulfillment timelines.Q: How is operator safety ensured during the welding process?

A: Operator safety is achieved through emergency stop features, overload protection, and interlock guards. The machine also includes a touch screen HMI for safe, efficient control and monitoring of the welding process.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Round Filter Cage Welding Machine Line Category

Round Filter Cage Welding Machine line WB-160

Price Range 1500.00 - 2500.00 USD ($)

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Feature : Other, High production speed, precise welding, customizable cage dimensions

Type : Automatic Welding Line

Weight (kg) : Approx. 2100 kg

Round Filter Cage Welding Machine line WB-100

Price Range 1000.00 - 2000.00 USD ($)

Minimum Order Quantity : 1 Piece

Material : Other, Mild Steel / Stainless Steel

Feature : Other, High precision welding, automatic feeding & discharging, reduced manual intervention, robust construction

Type : Fully Automatic

Weight (kg) : Approx. 3500 kg

Round Filter Cage Welding Machine line DLN-24-5

Price Range 20000.00 - 30000.00 USD ($)

Minimum Order Quantity : 1 Piece

Material : Other, Mild Steel

Feature : Other, High precision, efficient, easy operation, stable performance

Type : Automatic Welding Machine

Weight (kg) : Approx. 1200 kg

Venturi tube welder for filter bag cage DW-80

Price Range 3000.00 - 4000.00 USD ($)

Minimum Order Quantity : 1 Piece

Material : STEEL

Type : DW80

Send Inquiry

Send Inquiry