Talk to us

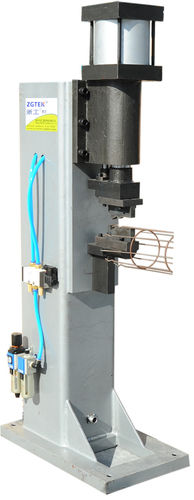

Round Filter Cage Welding Machine line WB-100

MOQ : 1 Piece

Round Filter Cage Welding Machine line WB-100 Specification

- Product Type

- Round Filter Cage Welding Machine Line WB-100

- General Use

- Automatic welding of filter bag support cages

- Material

- Mild Steel / Stainless Steel

- Type

- Fully Automatic

- Capacity

- Up to 80-100 cages/hour (varies by cage size)

- Weight (kg)

- Approx. 3500 kg

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC (Programmable Logic Controller)

- Filter Bag No.

- Configurable / Multiple variants possible

- Filter Area

- Depends on cage diameter and number of longitudinal wires

- Voltage

- 380V / 415V, 3-Phase, 50Hz

- Motor

- Main Motor 7.5 KW, auxiliary motors as required

- Dimension (L*W*H)

- Approx. 12000 mm x 1700 mm x 1800 mm

- Feature

- High precision welding, automatic feeding & discharging, reduced manual intervention, robust construction

- Color

- Industrial Grey / Customizable

About Round Filter Cage Welding Machine line WB-100

Round Filter Cage Welding Machine line WB-100

- Wire Bending Machine for Split Cages

- Model: WB-100

- Input voltage: 220V(1-phase) or specified by customer

- Air pressure: 0.6-0.8MPa

- Air flow: 150L/min

Advanced Welding Technology

The WB-100 uses resistance spot welding with a choice of pneumatic or electric actuation for consistent and high-quality welds. Design flexibility is offered with adjustable ring pitch and customizable cage diameters, ensuring compatibility with diverse filter cage specifications. Equipped with a touch-based HMI and PLC controls, the machine simplifies operator tasks and maximizes efficiency.

Superior Productivity and Integration

With an output capacity of up to 80-100 cages per hour, the WB-100 is engineered for high-volume manufacturing. Its automatic feeding, welding, and discharging systems minimize manual labor, while seamless integration capabilities enable it to work in tandem with forming and cutting lines. This results in streamlined processes and enhanced throughput.

User Safety and Robust Construction

Safety is paramount with the WB-100. It incorporates emergency stops, overload protection, and safety interlocks to create a secure working environment. The sturdy mild steel or stainless steel frame, along with an industrial-grade finish, withstands demanding factory settings while offering long-term reliability for daily operations.

FAQs of Round Filter Cage Welding Machine line WB-100:

Q: How does the WB-100 ensure consistent and high-quality welding of filter cages?

A: The WB-100 employs resistance spot welding technology with both pneumatic and electric actuation options, ensuring reliable and repeatable welds. Its programmable PLC and precise mechanical systems deliver high accuracy in wire placement, leading to consistently strong weld joints for every filter cage produced.Q: What is the process for adjusting cage diameter and ring pitch on this machine?

A: Cage diameter and ring pitch can be set and adjusted according to your design requirements using the touchscreen HMI interface. The machine accommodates diameters from 80 mm to 200 mm, and offers adjustable ring spacing, allowing easy configuration for various filter cage models.Q: When should maintenance be performed on the WB-100?

A: Routine maintenance should be scheduled as per the manufacturers guidelines, generally after every 1,000 operating hours, or sooner in case of intensive use. This includes checking welding contacts, pneumatic or electric components, and safety interlocks to ensure optimal performance and longevity.Q: Where can the WB-100 be integrated within a filter cage production line?

A: The WB-100 is designed for seamless integration with other filter cage forming and cutting lines. It can function as a core welding station in automated production setups, enhancing overall process flow and reducing manual material handling.Q: What operator training or skill level is required for using the WB-100?

A: Thanks to its intuitive touchscreen HMI and automated controls, the WB-100 can be operated by staff with basic machinery training. The manufacturer typically provides initial operational training and after-sales support for efficient onboarding.Q: How does the WB-100 benefit production facilities?

A: This machine enhances productivity through automatic feeding, high welding speed, and reduced manual intervention. Its robust safety features and precision controls help ensure high output quality, while its integration capability streamlines the overall cage manufacturing process, leading to improved operational efficiency.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Round Filter Cage Welding Machine Line Category

Round Filter Cage Welding Machine line D5I-80-2

Price Range 13000.00 - 15000.00 USD ($)

Minimum Order Quantity : 1 Piece

Control System : Other, PLC Controlled

Product Type : Round Filter Cage Welding Machine Line

Filter Bag No. : Up to 80 per cycle

Computerized : Yes

Round Filter Cage Welding Machine line DLN-24-6

Price Range 30000.00 - 50000.00 USD ($)

Minimum Order Quantity : 1 Piece

Control System : Other, PLC (Programmable Logic Controller) based

Product Type : Round Filter Cage Welding Machine Line

Filter Bag No. : 24

Computerized : Yes

Round Filter Cage Welding Machine line WB-160

Price Range 1500.00 - 2500.00 USD ($)

Minimum Order Quantity : 1 Piece

Control System : PLC Control

Product Type : Round Filter Cage Welding Machine line WB160

Filter Bag No. : Customizable as per requirement

Computerized : Yes

Round Filter Cage Welding Machine line LVV

Price Range 200.00 - 500.00 USD ($)

Minimum Order Quantity : 1 Piece

Control System : PLC Control

Product Type : Round Filter Cage Welding Machine line

Filter Bag No. : Multiple (customizable)

Computerized : Yes

Send Inquiry

Send Inquiry