Talk to us

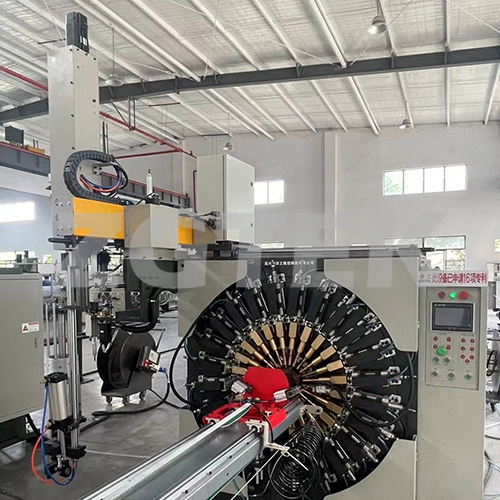

Automatic Filter Cage Welding Machine

Price 30000 USD ($)/ Unit

MOQ : 1 Unit

Automatic Filter Cage Welding Machine Specification

- Product Type

- Automatic Filter Cage Welding Machine

- General Use

- Filter cage manufacturing for dust collectors and filtration systems

- Material

- Mild Steel (MS) / Stainless Steel (SS)

- Type

- Fully Automatic

- Capacity

- 300-400 cages/8 hours (depends on cage size)

- Weight (kg)

- Approx. 2200 kg

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Based

- Filter Bag No.

- 6, 8, 10, 12, 16, 20, 24, or as customized

- Voltage

- 380 V / 415 V, 3 Phase, 50-60Hz

- Motor

- 3 HP 5 HP (customized as per requirement)

- Dimension (L*W*H)

- Approx. 4000 mm x 1200 mm x 1800 mm

- Feature

- High precision, low maintenance, user-friendly interface, energy efficient, consistent welding quality

- Color

- Blue/White (may vary by manufacturer)

- Welding Method

- Spot/Projection Welding

- Maximum Cage Length

- 2500 mm (customizable)

- Operator Requirement

- Single operator for automatic operation

- Air Pressure Requirement

- 0.5 0.8 MPa

- Maximum Cage Diameter

- 300 mm

- Wire Diameter Range

- 2 mm to 6 mm

- Minimum Cage Diameter

- 100 mm

- Welding Power

- 40-100 kVA (adjustable)

- Production Speed

- Up to 30 cages/hour (varies with design complexity)

- Minimum Cage Length

- 500 mm

- Application

- Baghouse filter cage production, industrial dust collection systems

About Automatic Filter Cage Welding Machine

Automatic Filter Cage Welding Machine

Specification

- Rings are pre-loaded into the machine so no need operators to insert rings one by one during welding.

- Model: DLN-24-5 Auto

- Cage wire quantity: 8/10/12/14/16/18/20/22/24

- Ring space: can be set at any value

- Cage outer diameter: 115-200mm

- Rail length: standard 7m, up to 10m can be customized

- Input voltage: 380V(2-phase) or customized

- Power frequency: 50/60Hz

- Designed max capacity of transformers: 80KVA

- Instant power in sync mode: 36KVA

- Instant power in async(time-sharing) mode: 18KVA

- Transformers: 2sets

- Air pressure: 0.6-0.8MPa

- Required ir flow: 300L/min

- Cooling method: natural cooling

- Weight: about 1500KGS

Features

- Very high welding speed, e.g. for a 12-wire cage, one ring takes only 0.18s

- Automatic cage pulling, ring space can be set in the program through the user-friendly interface.

- The cage pulling carriage is equipped with bearings, runs on the rail with linear guides, it's smooth and precise

- Function of bad weld detection and auto re-welding

- Material selection, different welding parameters for mild steel, galvanized steel and stainless steel

- Auto compensation gives enough space to insert the ring when the ring distance is short

- Ring space precision is 0.1mm; cage pulling speed is 0.4m/s

- Rails and material shelf equipped and connected to the machine. The front end of the rail is adjustment-free. Good linearity can be achieved for wire cages

- Four air tanks, short air route inside the machine ensures quick response of the cylinders

- 25mm thick front plate resulted from one-time machining, firmly secure that the welding cylinders are on the same plane and perpendicular to the axes, thus the linearity of the cage can be ensured

- Stroke-adjustable cylinders increase welding speed, pre-pressing only takes 0.08s

- Equipped with powerful micro-computing unit

- Sync/Time-sharing mode can put two transformers work at the same time or one after another, secure good welding quality even when the power supply is not very sufficient

Advanced Automated Production

This machine automates the entire filter cage welding process, requiring only a single operator for efficient operation. With computerized PLC control, it delivers precise, repeatable results at high speeds, producing 300-400 cages per 8-hour shift. Its advanced design reduces labor needs and maximizes efficiency in filter cage manufacturing.

Versatility in Design and Material

Capable of processing wires from 2 mm to 6 mm and cage diameters from 100 mm to 300 mm, the machine adapts easily to various filter bag specifications. It works with both mild steel and stainless steel, offering flexibility in material choice for diverse industrial dust collection applications.

User-Friendly and Low Maintenance

Featuring a simple interface and robust construction, the machine is easy to operate and maintain. Its energy-efficient design and reliable components minimize downtime and maintenance needs, making it ideal for continuous, high-volume production environments.

FAQ's of Automatic Filter Cage Welding Machine:

Q: How does the automatic filter cage welding machine operate?

A: The machine operates automatically with PLC-based controls. Operators load the wires, configure the desired cage parameters, and the machine handles the welding and cage formation using spot or projection welding. Only a single operator is needed for setup and monitoring.Q: What types of filter cages can the machine produce?

A: It can manufacture a wide variety of filter cages for baghouse and industrial dust collection systems. Supported configurations include cages with 6, 8, 10, 12, 16, 20, and 24 filter bags, and custom options are available for specific requirements.Q: When is it beneficial to use this machine in a production facility?

A: This machine is advantageous when high-volume, consistent-quality filter cages are required. It is ideal for continuous, large-scale production, especially where precision, reduced labor, and minimal maintenance are priorities.Q: Where is this machine typically used?

A: It is deployed in manufacturing plants specializing in filter cages for industrial dust collectors, primarily by distributors, manufacturers, exporters, and suppliers in applications requiring dust filtration systems-especially in regions such as Chile.Q: What is the welding process used by the machine?

A: The machine utilizes spot and projection welding techniques to securely join wire intersections, ensuring strong, precise, and uniform welds throughout each filter cage's structure.Q: What materials are compatible with this welding machine?

A: Both mild steel (MS) and stainless steel (SS) wires can be processed by the machine, providing versatility to match various industrial filtration applications.Q: What are the primary benefits of using this fully automatic welding machine?

A: The key advantages include high production capacity, reduced labor costs (single-operator requirement), energy efficiency, consistent weld quality, adaptability to different cage and wire sizes, and a low-maintenance, user-friendly operation.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Round Filter Cage Welding Machine Line Category

Round Filter Cage Welding Machine line DLN-24-6

Price Range 30000.00 - 50000.00 USD ($)

Minimum Order Quantity : 1 Piece

Capacity : Up to 24 filter cages simultaneously

Computerized : Yes

Feature : Other, High welding precision, continuous operation, energy efficient

Product Type : Round Filter Cage Welding Machine Line

Round Filter Cage Welding Machine line D5I-80-2

Price Range 13000.00 - 15000.00 USD ($)

Minimum Order Quantity : 1 Piece

Capacity : 80 filter cages/hour

Computerized : Yes

Feature : Other, Continuous Automatic Welding, High Precision, Error Alarm System

Product Type : Round Filter Cage Welding Machine Line

Round Filter Cage Welding Machine line LVV

Price Range 200.00 - 500.00 USD ($)

Minimum Order Quantity : 1 Piece

Capacity : 2040 cages/hour (varies by model)

Computerized : Yes

Feature : Other, High precision, efficient operation, easy to maintain

Product Type : Round Filter Cage Welding Machine line

Round Filter Cage Welding Machine line DLN-24-5

Price Range 20000.00 - 30000.00 USD ($)

Minimum Order Quantity : 1 Piece

Capacity : Up to 24 filter cages per cycle

Computerized : Yes

Feature : Other, High precision, efficient, easy operation, stable performance

Product Type : Round Filter Cage Welding Machine Line

Send Inquiry

Send Inquiry