Talk to us

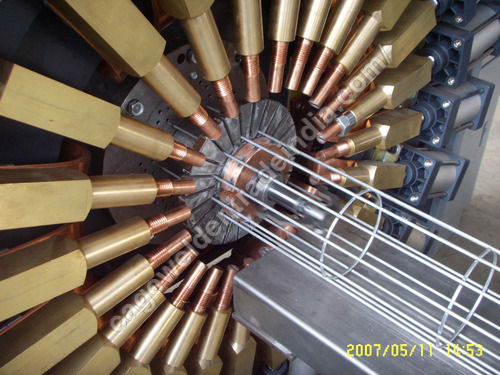

Oval Filter Cage Welding Machine

MOQ : 1 , , Piece

Oval Filter Cage Welding Machine Specification

- Application

- Filter Bag Cage Welding

- Equipment Type

- Filter Cage Welding Machine

- Phase

- Three Phase

- Frequency

- 50 Hz

- Power Source

- Electric

- Welding

- Spot Welding

- Output Voltage

- 15 32 V

- Diameter

- Customizable from 100 mm to 300 mm

- Power Consumption

- 10 kW/h

- Type

- Oval Filter Cage Welding Machine

- Condition

- New

- Motor Type

- AC Motor

- Material

- Mild Steel

- Power

- 10 kW

- Voltage

- 380 V

- Dimensions

- 3200 mm x 900 mm x 1800 mm

- Input Voltage

- 380 V

- Rated Current

- 25 A

- Rated Capacity

- Up to 20 cages/hour

About Oval Filter Cage Welding Machine

Oval Filter Cage Welding Machine

We have the required industry knowledge and technology to manufacture, supply and export Oval Filter Cage Welding Machine. These products are used in different industries for welding purposes. Owing to their high strength, low maintenance, better workability and effective operation, these products have a high demand in the international market. Oval Filter Cage Welding Machine is packed in special packaging material so as to ensure its safe and secure transit.

Specifications:

-

Model: DLN-10B/DLN-12B/DLN-16B

-

Wire Qty: 10/12/16

-

Ring Space: No restriction

-

Cage OD: standard size 64mm*148mm, rail length 9m, other sizes optional

-

Control Unit: KD-DL08D

Ring space is programmable and bag cage is pulled by mechanism formed by gear rack and step motor, no accumulated locating tolerance, ring space precision is 0.1mm, pulling speed is 0.4m/s, especially applicable to the bag cage with different ring spaces

Specification

-

Input Voltage: 380V(2 phase) or specified by customer

-

Power Frequency: 50/60Hz

-

Cooling Method: natural cooling

-

Air Pressure: 0.6-0.8 MPa

-

Insulation Grade: F

-

Power Capacity: 80 KVA

-

Instant power in sync mode: 36 KVA

-

Instant power in ASYNC (time-sharing) Mode: 18 KVA

-

Air Flow: 300 L/min

-

Weight: About 1300KG

Features

-

Rails (up to 9000mm) and carriage equipped and connected to the welding unit. The front end of the rail is adjustment-free. Good linearity can be achieved for wire cages

-

Equipped with auto feeding unit, no restrictions on ring space

-

Four air tanks, short air route inside the machine ensures quick response of the cylinder

-

25mm front plate resulted from one-time machining, firmly secure that the welding cylinders are on the same plane and perpendicular to the axes, thus the linearity of the cage can be ensured

-

Stroke-adjustable cylinders increase welding speed, pre-pressing only takes 0.08s

-

Controlled by micro-computing unit

- Time-sharing power-on transformer reduces the burden on local electricity grid

Filter Cages - round, star, oval, flat, peanut, spider and other odd shapes, with different connections, all can be customized.

Round cage size: OD100-200mm

Material: Mild steel wire, Stainless steel wire, Galvanized carbon steel wire, Titanium steel wire, etc.

Sizes of steel wire: 2.8-6mm

Precision Welding for Filter Bags

The Oval Filter Cage Welding Machine specializes in spot welding mild steel cages for filter bags. Designed for both efficiency and accuracy, it allows for customizable diameters to meet diverse filtration needs in industrial environments. Its advanced welding process ensures durable joints and minimal distortion, providing long-lasting performance for filtration applications.

Efficient and High-Capacity Production

With the capacity to produce up to 20 filter cages per hour, this machine streamlines cage assembly for large-scale operations. Its robust AC motor and stable power design ensure continuous and reliable output. The three-phase, 380 V configuration supports industrial efficiency, reducing downtime and increasing productivity.

FAQs of Oval Filter Cage Welding Machine:

Q: How does the Oval Filter Cage Welding Machine operate?

A: The machine uses a spot welding process to assemble mild steel wires into oval-shaped filter cages. Operators set the desired diameter, load components, and initiate the automatic welding cycle powered by a 10 kW AC motor. It maintains consistent voltage and current for reliable joints.Q: What are the key benefits of using this welding machine?

A: Key benefits include high throughput of up to 20 cages per hour, consistent weld quality, customizable cage diameters (100 mm to 300 mm), and energy-efficient operation. Its robust construction ensures minimal maintenance and longevity in demanding production settings.Q: When is this machine suitable for use in manufacturing?

A: This machine is ideal for manufacturing operations requiring high-volume, precise assembly of filter cage frames, such as in dust collector manufacturing, industrial filtration, or baghouse cage production. It is best suited for continuous, large-scale operations.Q: Where can the Oval Filter Cage Welding Machine be installed?

A: Due to its size (3200 mm x 900 mm x 1800 mm) and three-phase power requirements (380 V), the machine is typically installed in dedicated fabrication facilities, assembly lines, or industrial workshops with appropriate electrical infrastructure.Q: What is the process for customizing cage diameters?

A: The machine can be adjusted to weld cages with diameters ranging from 100 mm to 300 mm. Operators configure the diameter setting before loading materials, allowing flexible production runs to match specific order requirements.Q: How is power consumed during operation?

A: The Oval Filter Cage Welding Machine consumes 10 kW per hour during operation, powered by a 380 V, three-phase electric supply. This energy usage supports intensive spot welding and consistent production rates.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Filter Cages & Cage Parts Category

Filter Bag Cage Welder

Price Range 20000.00 - 30000.00 USD ($)

Minimum Order Quantity : 1 , , Piece

Output Voltage : Adjustable

Power : 7.5 kW

Condition : New

Material : Mild Steel Construction

Top Collar Welder for Filter Cage

Price Range 3000.00 - 4000.00 USD ($)

Minimum Order Quantity : 1 , , Piece

Output Voltage : 12V 24V

Power : 3 kW

Condition : New

Material : Mild Steel / Stainless Steel

Filter Bag Cage Welder

Price Range 20000.00 - 30000.00 USD ($)

Minimum Order Quantity : 1 , , Piece

Output Voltage : 32 V

Power : 7.5 kW

Condition : New

Material : Mild Steel

Guiding Plate Welder for Oval Cage

Price Range 10000.00 - 18000.00 USD ($)

Minimum Order Quantity : 1 , , Piece

Output Voltage : Adjustable, up to 24 V

Power : 2.5 kW

Condition : New

Material : Mild Steel

Send Inquiry

Send Inquiry