Talk to us

Round Filter Cage Welding Machine line DS-80

MOQ : 1 Piece

Round Filter Cage Welding Machine line DS-80 Specification

- Product Type

- Round Filter Cage Welding Machine Line

- General Use

- Welding and manufacturing round filter cages for dust collectors and filtration systems

- Material

- Mild steel structural frame with alloy components

- Type

- Automatic filter cage welding line

- Capacity

- 80 cages/hour (approximate)

- Weight (kg)

- 3500

- Computerized

- Yes

- Automatic

- Fully automatic operation

- Ozone Generator

- No

- UV Sterilizer

- No

- Control System

- PLC based touch screen interface

- Filter Bag No.

- Single or batch processing options

- Voltage

- 380V/415V, 3-phase, 50/60Hz

- Motor

- Main drive 7.5 kW, auxiliary motors included

- Dimension (L*W*H)

- 9000 mm x 1800 mm x 2200 mm

- Feature

- High speed cage welding, consistent weld quality, automatic straightening and rotary wire feeding

- Color

- Industrial grey/blue

- Operator Requirement

- 1 skilled operator

- Wire Diameter Range

- 3.0mm - 6.0mm

- Air Consumption

- 0.5 m³/min at 0.6-0.8 MPa

- Welding Type

- Resistance Spot Welding

- Power Consumption

- 14 kW (average working load)

- Production Process

- Automatic wire feeding, automatic rotary welding, cage ejection

- Cross Ring Spacing

- Adjustable, 50mm - 250mm

- Noise Level

- <75 dB(A)

- Cage Diameter Range

- 80mm - 250mm (custom options possible)

- Safety Features

- Emergency stop, overload protection, safety guards

- Cage Length Range

- 1000mm - 2500mm

- Number of Longitudinal Wires

- 8 to 24 wires (configurable)

About Round Filter Cage Welding Machine line DS-80

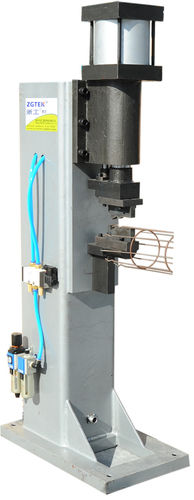

Round Filter Cage Welding Machine line DS-80- Top Collar welding machine for filter cage

- Specifically designed cyclinder ensures stable air pressure and welding speed

- One-piece machine body secures its rigidity

- Adopting KD-08B controller and reliable welding loop

- Top support locating flange and adjustable stand ensures the perpendicularity between the support and cage axis

- Top cap welder is also applicable for welding connecting rings for multi-section cages

Advanced Automation for Efficiency

The DS-80 welding machine boasts a fully automated process, from wire straightening and feeding to cage ejection. Managed by a PLC-based control system with touch screen interface, it reduces manual intervention, saves time, and ensures uniform welding results. Its robust automation not only increases productivity but also delivers reliable consistency for every filter cage produced.

Broad Customization and Versatility

With its adjustable wire and cage parameters, the DS-80 accommodates a wide range of specifications. Whether you require wires of varying diameters, different cage lengths, or unique cross ring spacing, this machine supports custom-configured production for diverse filtration requirements. It serves manufacturers, distributors, and traders seeking flexible, tailored filter cage solutions.

Safety and Operator-Friendly Design

The DS-80 prioritizes user safety with integrated emergency stop controls, overload protection, and safety guards around moving parts. Its intuitive PLC touch screen minimizes learning curves and ensures that one skilled operator can effectively supervise the entire process, making it both safe and user-friendly for production staff.

FAQs of Round Filter Cage Welding Machine line DS-80:

Q: How does the DS-80 Round Filter Cage Welding Machine enhance cage production efficiency?

A: The DS-80 automates wire feeding, rotary welding, and cage ejection, allowing a single skilled operator to supervise the production of up to 80 cages per hour. This significantly increases throughput and reduces manual labor, ensuring greater efficiency in filter cage manufacturing.Q: What is the process for setting up the machine for different cage and wire sizes?

A: Changing cage or wire sizes involves selecting the desired parameters on the PLC touch screen (such as wire diameter, cage diameter, number of wires, and spacing). The machines adjustable components and automatic wire straightening make it easy to quickly configure for custom production runs.Q: Where is the DS-80 filter cage welding machine typically used?

A: This machine is primarily used in facilities manufacturing dust collector and filtration system filter cages. Manufacturers, exporters, importers, and distributors in related industries benefit from its robust and adaptable design for both single and batch processing.Q: When should operators consider customizing machine settings?

A: Operators should adjust machine settings whenever specific filter cage requirements change, such as altering wire diameter, cage length, or the number of longitudinal wires. The DS-80s flexibility makes it ideal for varying production needs and special orders.Q: What safety features are built into the DS-80 machine?

A: Key safety features include an emergency stop button, overload protection mechanisms, and extensive safety guards to prevent operator injury. These ensure safe, reliable operation during high-speed automated welding cycles.Q: How does the DS-80 ensure consistent weld quality?

A: The resistance spot welding method, automatic rotary welding system, and PLC control guarantee uniform pressure and timing for each weld, resulting in high consistency and strength across all filter cages produced.Q: What are the benefits of using a fully automatic, computerized filter cage welding machine?

A: Fully automatic, computerized operation minimizes human error, increases production speed, and enables precise parameter control, leading to superior weld quality, reduction in labor needs, and increased overall cost-effectiveness for filter cage manufacturers.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Round Filter Cage Welding Machine Line Category

Round Filter Cage Welding Machine line WB-160

Price Range 1500.00 - 2500.00 USD ($)

Minimum Order Quantity : 1 Piece

Feature : Other, High production speed, precise welding, customizable cage dimensions

Material : Stainless Steel

Weight (kg) : Approx. 2100 kg

Voltage : 380V, 50Hz

Round Filter Cage Welding Machine line DLN-24-6

Price Range 30000.00 - 50000.00 USD ($)

Minimum Order Quantity : 1 Piece

Feature : Other, High welding precision, continuous operation, energy efficient

Material : Other, Mild Steel (MS)

Weight (kg) : Approximately 3000 kg

Voltage : 380 V / 415 V, 3 Phase, 50 Hz

Round Filter Cage Welding Machine line D5I-80-2

Price Range 13000.00 - 15000.00 USD ($)

Minimum Order Quantity : 1 Piece

Feature : Other, Continuous Automatic Welding, High Precision, Error Alarm System

Material : Other, Mild Steel Frame with Heavy Duty Components

Weight (kg) : Approx. 2500 kg

Voltage : 380V / 50Hz, 3 Phase

Round Filter Cage Welding Machine line LVV

Price Range 200.00 - 500.00 USD ($)

Minimum Order Quantity : 1 Piece

Feature : Other, High precision, efficient operation, easy to maintain

Material : Other, Mild Steel / Stainless Steel

Weight (kg) : 1500 kg (approx.)

Voltage : 380V/415V, 3 Phase, 50/60Hz

Send Inquiry

Send Inquiry